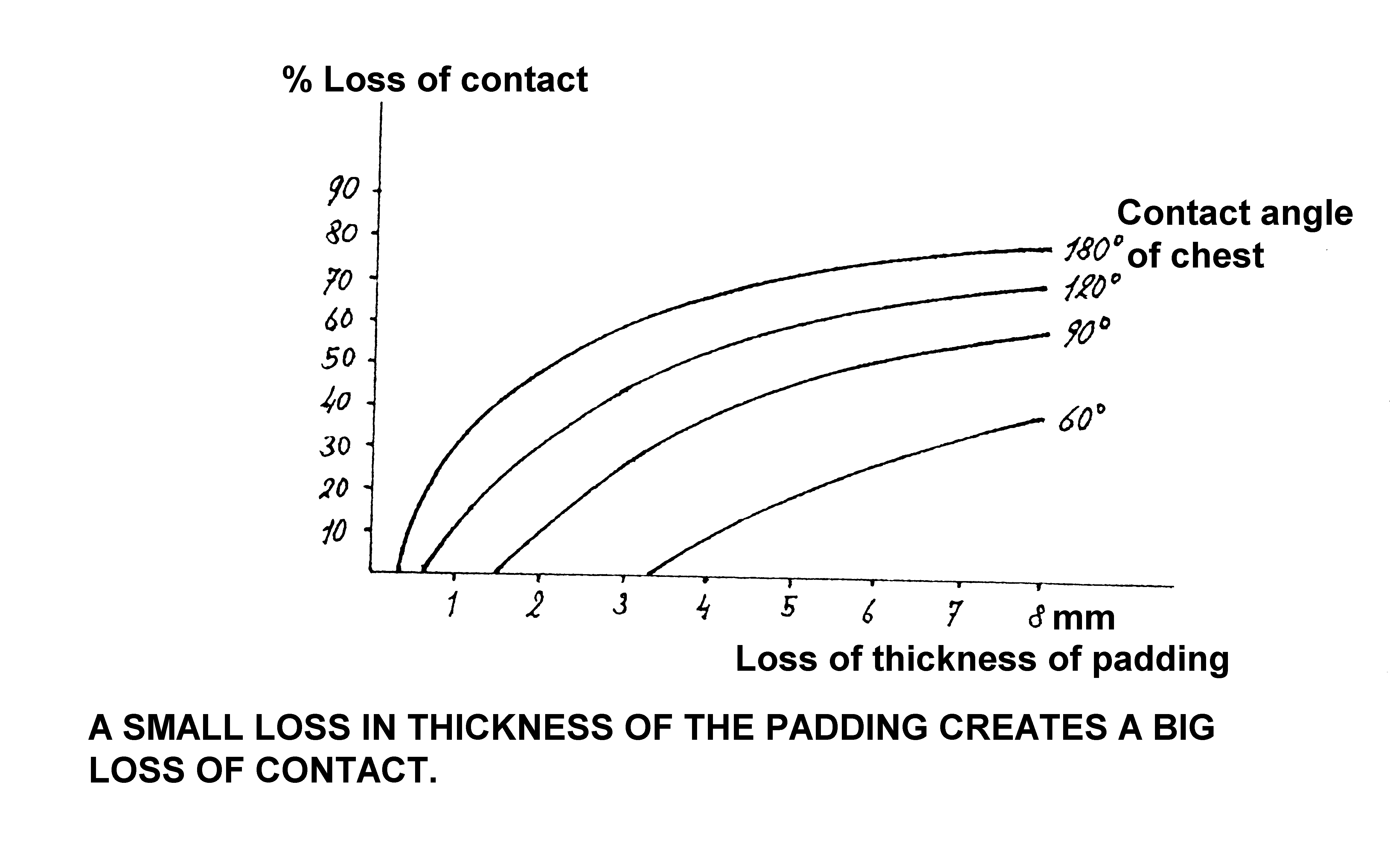

The output of a flatwork ironer depends mainly on the good contact between the linen and the heated chest. The smallest loss in diameter of the roll is reducing considerably the production capacity. On modern ironers width deep chests and large diameter 2 mm loss of the padding thickness will reduce this capacity by 40 % ( see graph.)

Most ironers used today have spring padding and thin top padding Soft springing have more resiliency and more tolerance to the size of the chest. The size of the chest can vary slightly depending on the steam pressure and the temperature (thermal fluid)

SPRINGTAPE : Benefits from a high tolerance to the size of the chest ( S more than the H type) and will be compressed by the ironing pressure ; it will compensate the wear of the top padding and guaranties a constant production of the machine throughout the padding life. SPRINGPAD : 100 % stainless steel and is extremely corrosion resistant. SPRINGPAD is the first soft laminated spring, it holds perfectly the top padding in place thanks to the hooks on the top of the springs.